In 2006 Sound Lab introduced a major upgrade to our panel technology. This was prompted by our desire to introduce electrostatic speaker technology to the commercial sound market. In order to accomplish this the sensitivity, output capability, physical ruggedness and reliability of the speakers needed to be competitive with conventional commercial speakers. This exercise was successful and we felt that the improvements should be incorporated into our high-end audiophile speakers. Therefore, the professional technology was extended to our audiophile speaker line. To clearly differentiate speakers using the new technology the suffix PX (professional extension) was added to model numbers.

Three major areas of panel design are affected by PX technology: stators , panel structure and the membrane.

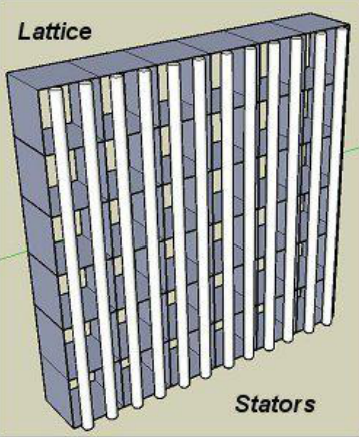

Stators: Instead of stator wires being self-supported, as was our original stator design, PX stator wires have a lattice backing to increase their rigidity. The reason for this is that under high driving conditions, the reactive force exerted on the original stator wires could cause them to move slightly toward and away from the membrane in sync with the applied signal. This causes a small consequential loss of transduction efficiency and can introduce unwanted resonances. This PX lattice “backbone” effectively eliminates stator wire movement and thus provides maximum panel efficiency and eliminates stator resonance. Furthermore, the stator wire insulation used with PX technology is an irradiated cross-linked material that provides the most physically and electrically rugged insulation material available for this application.

Panel structure: The PX panel frame designed for the new stators is stronger and stiffer than the previous panel frames. This is due to the newly introduced computer-precision mechanical interlocking of frame members along with the use of threaded steel screw fasteners to secure the members together. This is in contrast to the previous standard of adhesive and staples. The PX panels are designed to meet the greater demands of commercial and professional sound applications.

Membrane: The membrane film consists of a tough polyester polymer having a thickness on the order of only 100 millionths of an inch. A very thin uniform, electrically-conductive film is applied to the membrane which is protected with a micro-coating of Teflon to seal out moisture and other contaminants that could affect the uniformity and characteristics of the coating. The membrane is locked onto the panel frame permanently such that slippage is not a possibility. As a result, membrane tension is preserved indefinitely.

Original panels cannot be updated to PX technology: The increased thickness of the stators, due to the lattice backbone, requires a panel frame that is designed to accommodate it. As a result, this update cannot be applied to earlier panels. However, the original panels can be replaced with PX panels for those who wish to have the advantages of PX technology.

Finale: PX technology has increased the performance and reliability of our products to the degree that we refer to them, with statistical backing, that they are a “forever” speaker. The response from customers who have replaced their standard panels with PX panels has been very positive.